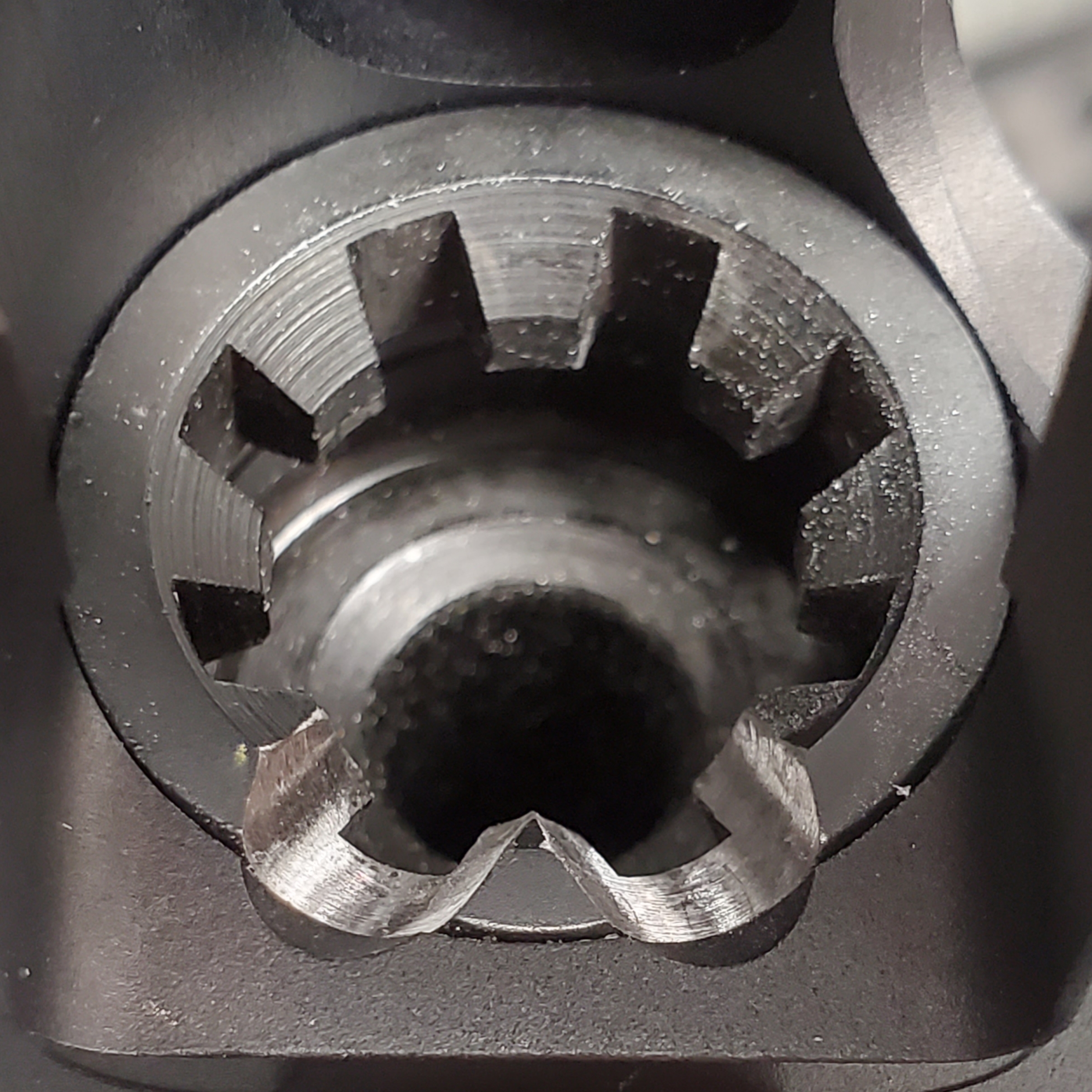

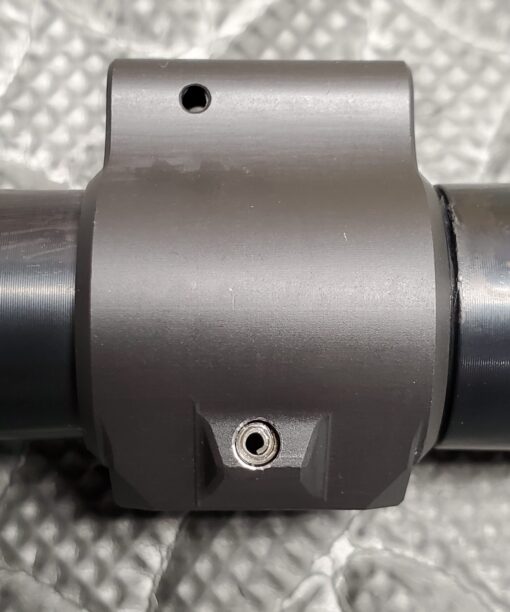

Barrel Feed Ramp Polishing Service

$60.00

Out of stock

Our barrel feed ramp polishing service is meant to improve the feeding step of the cycle of operations. It can be done to repair misaligned feed ramps or just to soften the violent feeding process.

Often times a barrel extension will be slightly twisted or stick into the receiver and create a burr that bullets will catch on and cause feeding issues. To check for feed ramp issues, use a soft, square edged tool like a match stick to slide up each ramp in multiple areas to ensure there are no snags. If the tool snags anywhere on the ramps, including the edges, you should consider having the barrel and receiver inspected and possibly re-cut if necessary. In cases like this, we will use several gauges and methods to inspect the rifle to make sure that there isn’t another cause that needs to be addressed first. If the barrel is straight with the upper receiver and no other issues are found, we will cut the ramps to re-align with the ramps in the receiver. Once a proper profile has been achieved, the ramps are then polished to a high shine.

Polishing can help smooth out roughly machined feed ramps as well to improve feeding. Barrel feed ramp polishing in many cases can reduce the amount of metal shavings introduced into the receiver since rough edges and burrs will be removed in the process. If the barrel extension is treated with a surface treatment like nitriding or NP3, we generally don’t recommend polishing unless there is an alignment issue.

Care is taken to not to change the angle of the ramps which could could cause further feeding issues. We also do not cut the upper receiver since removal of the protective anodized finish would allow the bullets to erode the aluminum over time. Because of this will need to remove the barrel from the upper receiver. We also wont cut M4 style ramps into an upper receiver to make it match the barrel extension. The barrel and receiver ramp styles should not be mismatched.

See our post on Instagram about barrel feed ramp polishing

| Polish only or recut? | Polish Only, Recut and Polish |

|---|

1 review for Barrel Feed Ramp Polishing Service

Add a review Cancel reply

Related products

Gunsmithing Services

Gunsmithing Services

Gunsmithing Services

Gunsmithing Services

Gunsmithing Services

Daniel Maltz (verified owner) –

This service is amazing! I’ve had Alex do this on a few of my barrels so far. Alex will take your feed ramps and match them up seamlessly to your upper. It’s so perfect it looks like the parts were built specifically to be mated together. I don’t know how he does it so precisely, but it’s like a work of art, especially with that mirror finish! I have no doubt this will make the feeding cycle of operation as smooth as glass. Now I want this on all my barrels just because it’s so cool!